Think3 Software

Would you like to try our software on your machine. You can download our free trial with limited functionality. Download Now. If think3 has its way, the software company will change the way mechanical design is done in the $9 billion computer-aided design (CAD) market. Here's the lowdown on. California Work Release Program Inmates. Taking into account the confusion among Think3 customers regarding the two sources of software and support for the Think3 line of products, Andrea Ferri, the court. We provide CAD users with powerful digital prototyping solutions. Join our community and explore the benefits of using ThinkDesign CAD software.

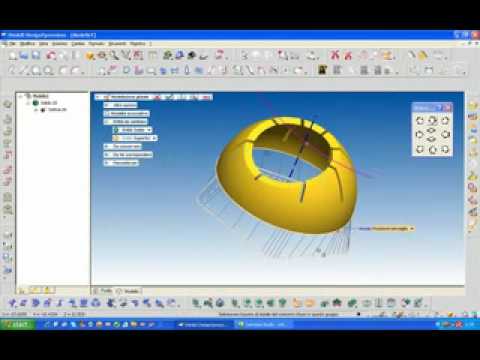

DPT offers All advanced surface modeling features Mold Design & Die Design Compensator & Reverse Engineering Rendering ThinkDesign Professional allows the removal of the barriers to the communication in the various stages of the product definition since it is possible to make changes without losing the work done in other departments. In fact, thanks to the benefits of solid modeling, to the flexibility of the models of free-shape surfaces and to the extraordinary editing tool of GSM, modifications can be made with great creativity and precision to any type of shape, no matter if native or imported ones, while maintaining the full associativity and in a much shorter time than with the traditional approaches. Thanks to a set of extraordinary functionalities, the project finally materializes and turns into the product. DPT offers Full Hybrid Modeling tools Global Shape Modeling (GSM) & Zone Modeling Standard converters to import third-party files Rendering ThinkDesign Tooling features innovative technologies that allow real-time modifications of complex models, libraries of 3D components and the most popular commercial catalogs. Since the management of files in various CAD formats of varying quality levels is a great challenge, it is very important to have the right tools to easily modify the models in neutral formats (IGES, STEP, etc.). A key element of the mold design process is still made in a “mixed environment” that brings together the speed of 2D and the quality and accuracy of surface and solid modeling: for this reason, TD Tooling offers a single 2D/3D integrated design environment.