Austempering Martempering Pdf

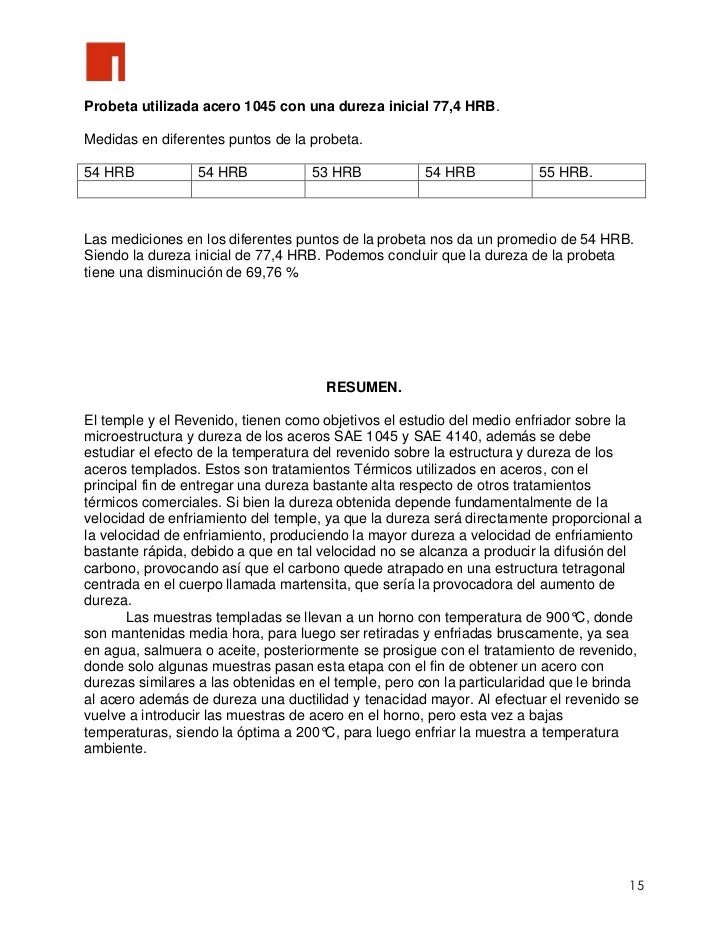

Pearlite is fine and usually appears unresolved with optical microscope. Grain size distribution is slightly less uniform. Buku Yaasinn Dan Tahlil Bahasa Arab Latin. Internal stresses are slightly more. Figure 4.7.5 Normalizing [3]. Different techniques to improve the hardness of the steels are conventional hardening, martempering and austempering. Austempering and martempering pdf Austempering and martempering pdf Austempering and martempering pdf DOWNLOAD! DIRECT DOWNLOAD! Austempering and martempering pdf.

Martempering is also known as stepped quenching or interrupted quenching. In this process, steel is heated above the upper critical point (above the range) and then quenched in a,, or bath kept at a temperature of 150-300 °C.

The workpiece is held at this temperature above martensite start (Ms) point until the temperature becomes uniform throughout the cross-section of workpiece. After that it is cooled in air or oil to room temperature. The steel is then. In this process, is transformed to by step, at a rate fast enough to avoid the formation of,. In the martempering process, austenitized metal part is immersed in a bath at a temperature just above the martensite start temperature (Ms).

By using interrupted quenching, the cooling is stopped at a point above the martensite transformation region to ensure sufficient time for the center to cool to the same temperature as the surface. The metal part is then removed from the bath and cooled in air to room temperature to permit the austenite to transform to martensite. Martempering is a method by which the stresses and strains generated during the quenching of a steel component can be controlled. In Martempering steel is heated to above the critical range to make it all austenite. The drawback of this process is that the large section cannot be heat treated by this process. See also [ ] • • References [ ].

Abstract The mechanical properties of steel decide its applicability for a particular condition. Heat treatment processes are commonly used to enhance the required properties of steel. The present work aims at experimentally investigating the effect of austempering and martempering on AISI 52100 steel.

Different tests like microstructure analysis, hardness test, impact test, and wear test are carried out after heat treatment process. It was found that annealed steel was least hard and more wear prone, while martempered steel was hardest and least vulnerable to wear. Austempered steel had the highest impact strength and it is increased with soaking time up to certain level. Least wear rate is observed in martempered sample both in abrasion and dry sliding. However, least friction coefficient is shown by annealed samples.